From Pieces to Sets: How Our Bricks Are Packed with Precision

Share

When you open a brand-new brick set and see all the pieces neatly arranged, it’s easy to forget the journey each piece has taken to get there. Today, we’re taking you behind the scenes at our factory to show you exactly how it happens.

1. The Birth of a Piece

Every brick starts with high-precision molds in an injection molding machine. ABS material is heated to the perfect temperature, injected into the mold cavity, and cooled to form a durable, vibrant piece. Once molded, the bricks pass through an initial inspection, where any that have color deviations or defects are removed.

2. Intelligent Sorting

The approved pieces move into a high-speed sorting machine. At its core is a combination of vibrating feeders and precise weighing systems. Based on a detailed packing list for each SKU, the machine automatically distributes the exact number and type of bricks into separate packaging channels. Each channel corresponds to a specific “bag unit,” ensuring the right mix of pieces ends up in every bag.

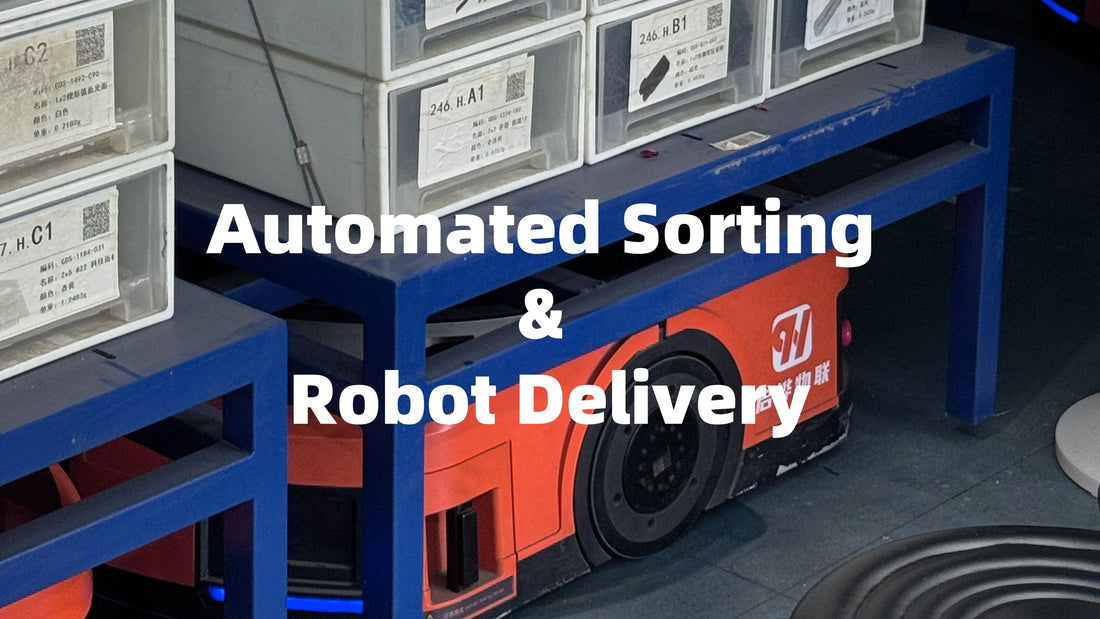

3. The Mini Logistics Robots

Once bagged, the pieces don’t just sit around. They’re picked up by our “mini logistics robots” — small, self-driving vehicles that navigate the factory floor. Guided by the packing schedule, they deliver the correct bags to the right packing stations, adjusting their routes in real time to keep everything running smoothly.

4. The Set Comes Together

At the packing station, all the bags, instruction manuals, and any special components come together. Our staff carry out a final quality check before placing them into the printed box. After sealing, coding, and boxing, the sets are ready to begin their journey to brick fans around the world.

This seamless blend of automation and human oversight doesn’t just speed up production, it also minimizes errors, so every customer can enjoy a flawless building experience right out of the box.